What is container stowage planning.??

Simply put, it is the act of allocating space to containers on board of a container ship in the order of the discharge ports.

SimpleStow allows you to simulate shifting or re-stowage of containers in intermediate ports. Thus a container may have different stowage positions in different ports during the voyage. Thus a container may have different stowage positions in different ports during the voyage.

This is a topic of great importance and is my favourite activity in the whole realm of container shipping operations.

SimpleStow allows you to simulate shifting or re-stowage of containers in intermediate ports. Thus a container may have different stowage positions in different ports during the voyage. SimpleStow uses the order of ports during the voyage to detect possible overstowage due to port rotation. This market leading software provides the ideal tool for ship planning and stowage coordination. It is both powerful and versatile, meeting the needs of today's ship operations, including the complexities of joint services, consortia and slot sharing agreements, transhipments, terminal ship planning.

Tools required :

Super mario galaxy 2 wii iso ntsc download. Super Mario Galaxy 2 (USA) WII ISO Download for the Nintendo Wii. Game description, information and WAD/WBFS/ISO download page.

- The scheduled list of ports that the ship will be calling at, in the order of rotation

- A summary of the number of containers – size/type/weight of containers per port that are planned to be loaded on the ship

- A summary of the number of hazardous, reefer and OOG containers per port that are planned to be loaded on the ship

- List and summary of containers that are on board after discharge of the containers at your port. for the purposes of this article, we will consider this port to be Durban.

Definitions :

Profile – is the cross sectional view of the entire ship covering both the deck and under-deck of the ship.

Bayplan – is the complete cross sectional view of the entire ship covering both the deck and under-deck of the ship, but displayed or printed per bay

Bay – each container vessel is split into compartments which are termed as Bay and depending on the size of the ship it will proceed from 01 to 88 bays (you can read my take on an interesting comparison between stowage plans of older ships and current Triple E type ships) where Bay 01 is the bay towards the Bow (the front) of the ship and Bay 88 is the Stern (the back) of the ship.

Odd numbered bays (1,3,5 etc) means that it is a 20' stow and Even numbered bay (2,4,6 etc) means that it is a 40' stow.

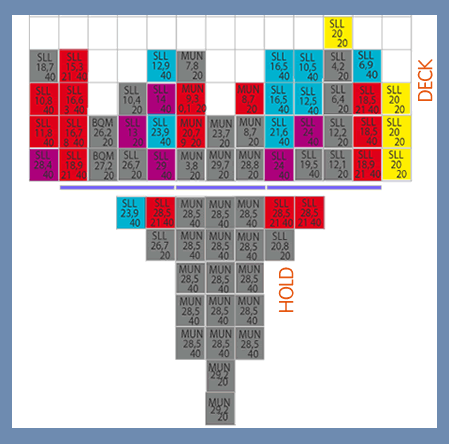

Confused.?? Look at the below picture. I have used Bay 09/11 (10) and Bay 13/15 (14) as an example here. What you are seeing here is the cross section of the ship both on deck and under deck. Each of the small square blocks represents a 20' unit space.

Row is the position where the container is placed across the width of the ship. If you refer to the above diagram, the Row numbers are circled in Green. It starts with 01 in the center and progresses outwards with odd numbers on the right (starboard) and even numbers on the left (port).

Tier denotes at which level the container is placed – basically how high the container is stacked on board. In the above diagram, the Tier numbers are circled in Red.

Hatch Covers (the dark intermittent lines in the above picture) are the covers that separate the deck from the under-deck. The area above the line is called the deck (which is generally visible to us when we look at the ship) and the area below the line is called under-deck (which is not visible to us from outside the ship).

The planning is mainly done on a document called a 'profile' which can be viewed below.

The profile provides the full cross section of a ship at one glance. The enlarged version of this will be the actual bay itself. Currently, the stowage planning is mostly done via computers.

Although the computers do most of the work, the basis on which they work is the tried and tested methods that have been followed for many years around.

- the list of containers that are to be loaded on board are segregated by destination.

- space is allocated to each of the containers

- firstly in the order of destination – the farthest destination at the bottom and the next port of call right on top

- secondly in the order of weight – the heaviest boxes at the bottom and lightest at the top

For reasons of lashing and securing containers, a 40' container can sit on top of two 20's, but two 20's cannot sit on top of 40' (unless it is under deck and surrounded by other containers or within cell guides).

In the above profile I have used various alphabets and colors.

- F for Felixstowe

- A for Antwerp

- Ae for Antwerp Empty

- H for Hamburg

- L for Le Havre

- R for Rotterdam

- X to indicate that its a 40' contr.

The rotation for this vsl is Felixstowe, Antwerp, Le Havre, Hamburg and Rotterdam. So as you can see, Felixstowe containers are stacked right on top of other containers as this will be the first port of call after Durban.

Rotterdam will be the last port of call hence it is right at the bottom of the heap. In this fashion the entire ship is filled with the containers that are to be loaded at each load port while also taking into account the containers that are ALREADY present on board from the previous ports.

If you notice in the image on the right, there is a container in stow position 110910 (Bay 11, Row 09, Tier 10) – circled in red and marked L for Le Havre. If you want further info on how to read the bay plan, please read https://shippingandfreightresource.com/2009/03/31/identifying-a-stow-position/).

Let's assume that this container was wrongly stowed for Le Havre instead of Felixstowe or a restow was requested at a later stage to now discharge this container in Felixstowe.

In order to reach this container, all the 12 containers meant for Antwerp (A and Ae) has to be 'restowed' (taken off the ship and landed on the wharf side and put back on board once this box is taken out) because Antwerp is the next port after Felixstowe.

Then the hatch cover (the dark line between the deck and under deck) has to be opened to reach under deck.

Then the 1 container to Le Havre (L) in position 110912 must be 'restowed' as well and only then the container in position 110910 can be discharged in Felixstowe.

As you can imagine, this involves considerable cost and wastage of time for the ship to restow 12×40′ containers and 1×20′ container to discharge this one container that was stowed incorrectly.

So to avoid these costs and wastage of time, it is highly imperative that the right destination, right weight, and haz info if any is accurately passed onto the ship.

Every step in production intentionally planned out for superb quality. A good number of the Ibach meisters we had trained under in Germany stayed with us for our beginning production. https://delsotenness1988.mystrikingly.com/blog/baus-piano-serial-number. New tooling was utilized in precision execution, compounded by unending regulation and scrutiny. In 1993 we began production at home under strict contract for Ibach. The German process was quite different from what had been our own.

No Stowage

English stylish fonts free download zip file. Each of the bays have deck stress or tier weight which is the maximum allowed weight that each of the tier/row can carry as per the design of the ship.

In the above profile I have used various alphabets and colors.

- F for Felixstowe

- A for Antwerp

- Ae for Antwerp Empty

- H for Hamburg

- L for Le Havre

- R for Rotterdam

- X to indicate that its a 40' contr.

The rotation for this vsl is Felixstowe, Antwerp, Le Havre, Hamburg and Rotterdam. So as you can see, Felixstowe containers are stacked right on top of other containers as this will be the first port of call after Durban.

Rotterdam will be the last port of call hence it is right at the bottom of the heap. In this fashion the entire ship is filled with the containers that are to be loaded at each load port while also taking into account the containers that are ALREADY present on board from the previous ports.

If you notice in the image on the right, there is a container in stow position 110910 (Bay 11, Row 09, Tier 10) – circled in red and marked L for Le Havre. If you want further info on how to read the bay plan, please read https://shippingandfreightresource.com/2009/03/31/identifying-a-stow-position/).

Let's assume that this container was wrongly stowed for Le Havre instead of Felixstowe or a restow was requested at a later stage to now discharge this container in Felixstowe.

In order to reach this container, all the 12 containers meant for Antwerp (A and Ae) has to be 'restowed' (taken off the ship and landed on the wharf side and put back on board once this box is taken out) because Antwerp is the next port after Felixstowe.

Then the hatch cover (the dark line between the deck and under deck) has to be opened to reach under deck.

Then the 1 container to Le Havre (L) in position 110912 must be 'restowed' as well and only then the container in position 110910 can be discharged in Felixstowe.

As you can imagine, this involves considerable cost and wastage of time for the ship to restow 12×40′ containers and 1×20′ container to discharge this one container that was stowed incorrectly.

So to avoid these costs and wastage of time, it is highly imperative that the right destination, right weight, and haz info if any is accurately passed onto the ship.

Every step in production intentionally planned out for superb quality. A good number of the Ibach meisters we had trained under in Germany stayed with us for our beginning production. https://delsotenness1988.mystrikingly.com/blog/baus-piano-serial-number. New tooling was utilized in precision execution, compounded by unending regulation and scrutiny. In 1993 we began production at home under strict contract for Ibach. The German process was quite different from what had been our own.

No Stowage

English stylish fonts free download zip file. Each of the bays have deck stress or tier weight which is the maximum allowed weight that each of the tier/row can carry as per the design of the ship.

For example if there are about 4 containers in a tier each weighing 26 tons, it may not be possible to accommodate all 4 in one tier as this might affect stability due to the heavy nature of the cargo.

However, if there are 5 tiers of empty containers as shown in Bay 15, it might be possible to load. These calculations will be performed by the computer itself and it will show up as errors.

Jun 20, 2012 Lightworks dari editor untuk editor software lightwork di design khusus untuk para editor, dengan tampilan cantik dan fitur dan kemampuan sebagai editor video handal untuk produksi atau menghasilkan video berkualitas, layaknya vegas pro atau adobe premiere pro Download| File: 125MB File Lab Video editor Online editor untuk editing video. Ini dia 10 software edit video terbaik. Aplikasi Download Flim Gratis Android. Cara Download Film Di HP Android Mudah dan Gratis! APPS TERKAIT. Download software edit video terbaik gratis.

Some of the most commonly used software for ships planning are CASP, MACS3 and Bulko. These use the BAPLIE file format structured by UNEDIFACT.

Also interesting to note that a lot of Container stowage is done in centralised hubs these days.